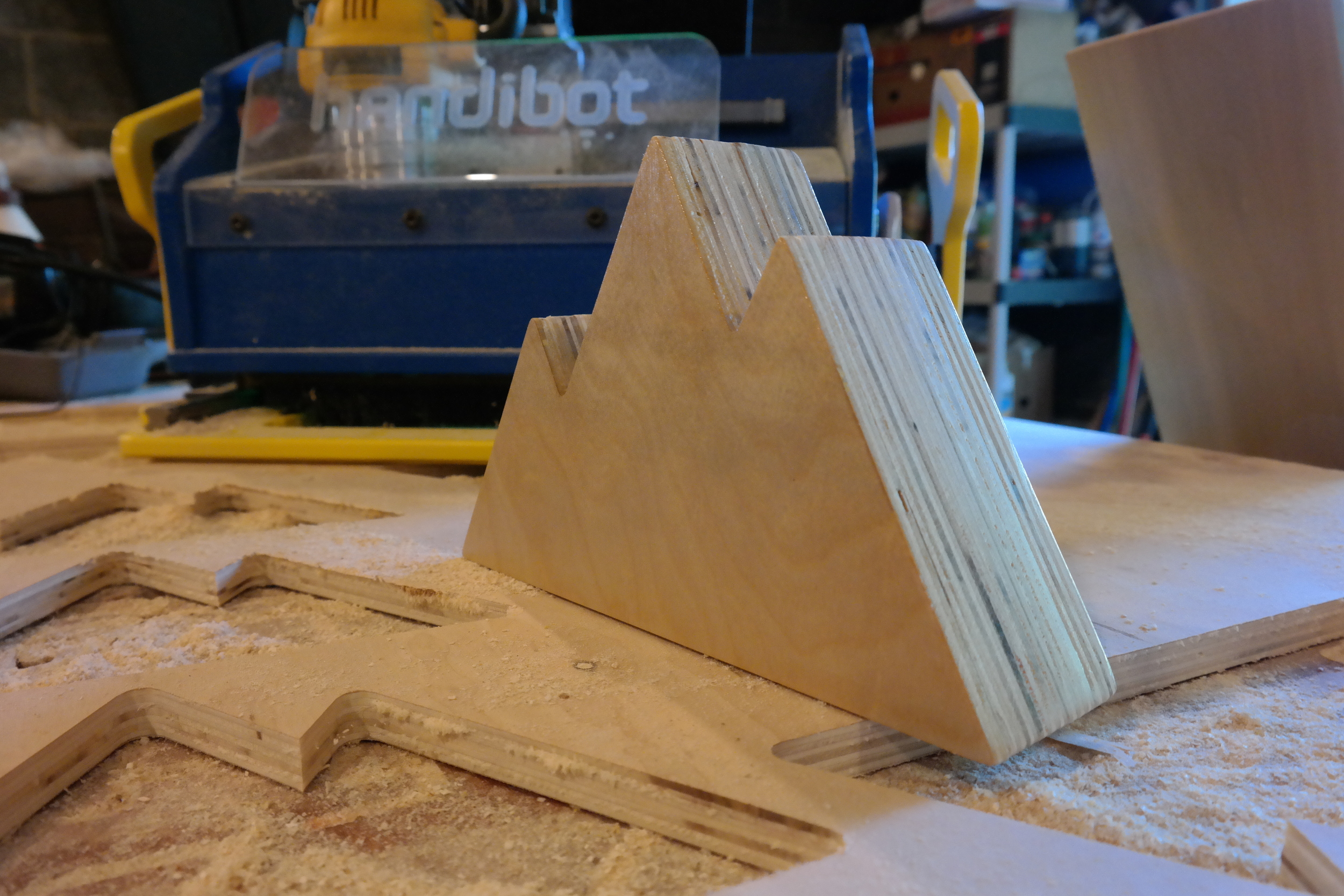

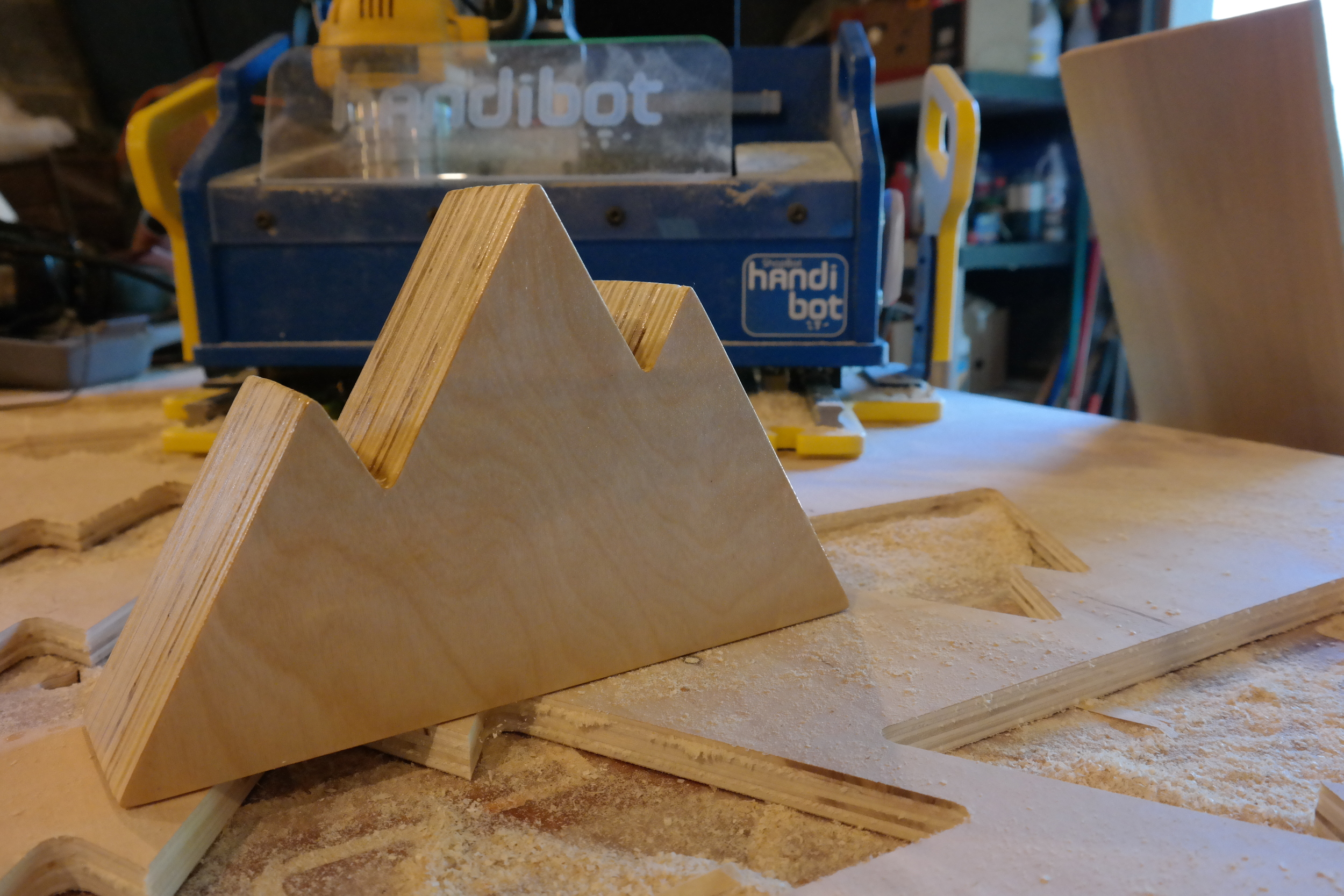

I had an occasion to make a gift box on my Handibot. The person who was receiving the gift really likes mountains. I decided to make a very simple mountain shaped box that could hold things, and look good on a shelf. As usual I modeled it in Sketchup first:

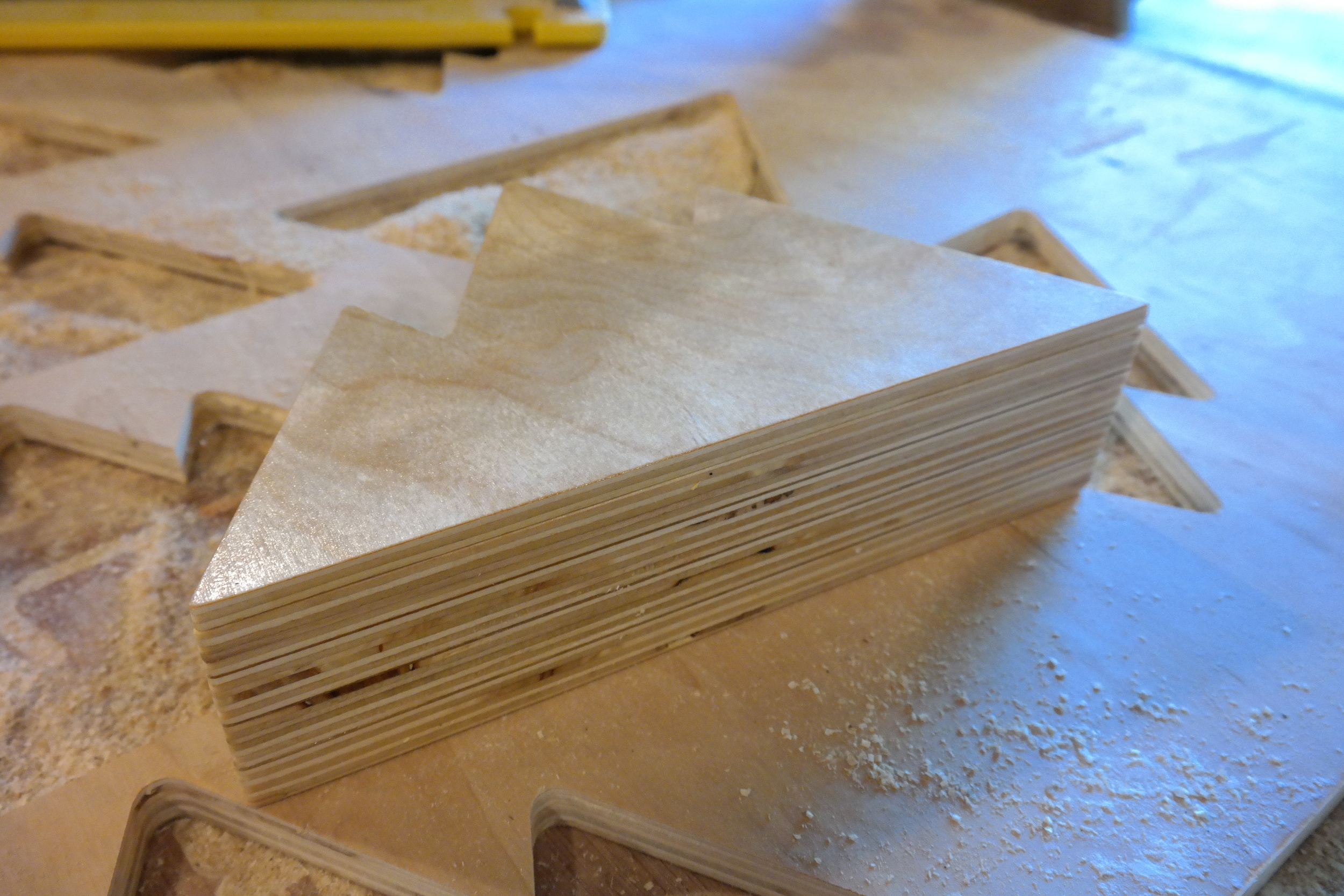

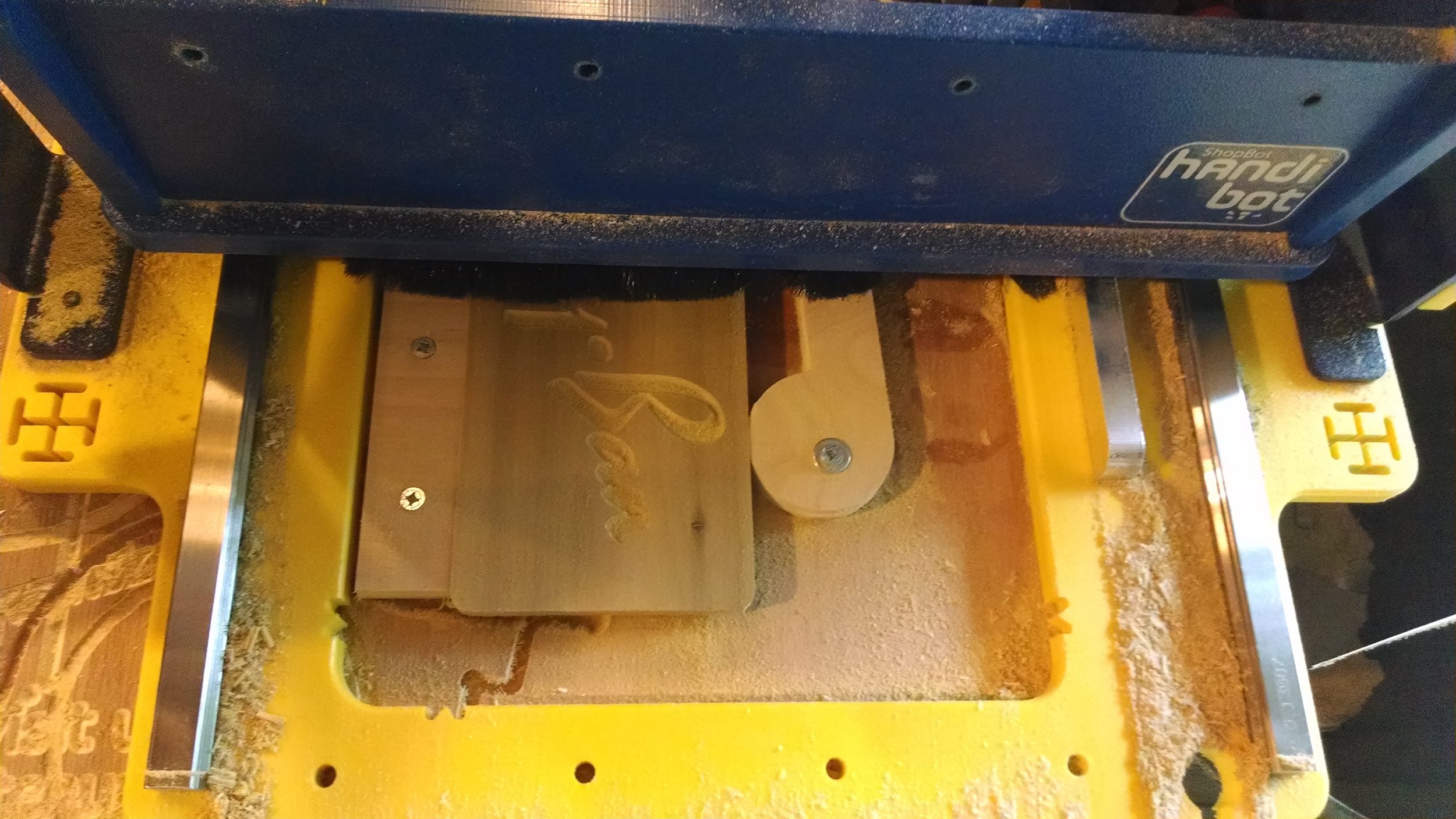

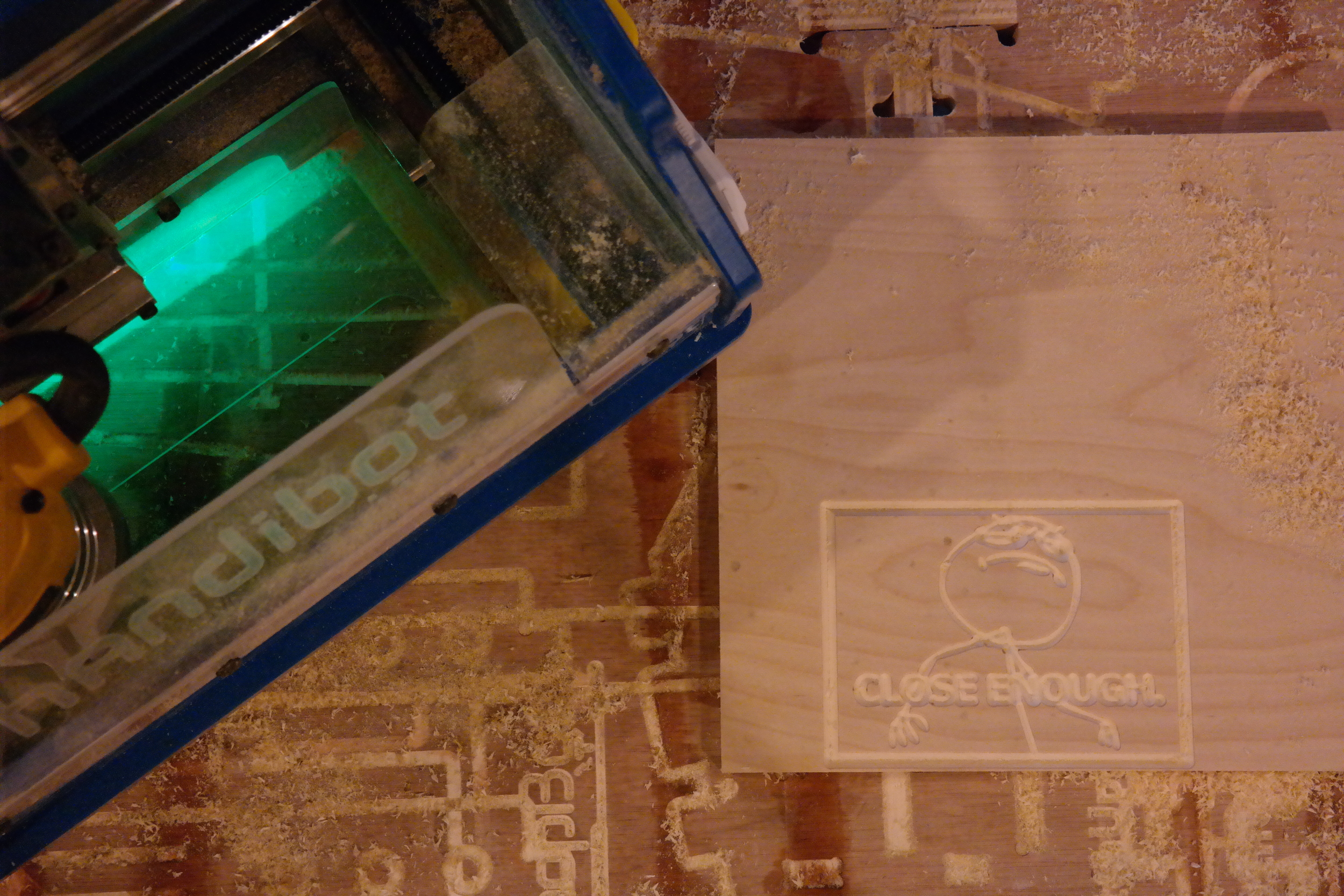

After that I brought it into VCarve Pro, setup my toolpaths and milled all the parts. You can see in this shot below how I milled the top. I just did it upside down and milled the "lip" into the wood, and then cut out the rest. I added a .02" tolerance so the top fit loosely enough into the box to not fall out, but not be hard to open. There can be a little trial and error getting just the right tolerance.

Here are the results! After a little Shellac this box came out really nicely! If you want to cut your own, feel free to download this project using the button below. The Sketchup model, VCarve file, and images are all included.